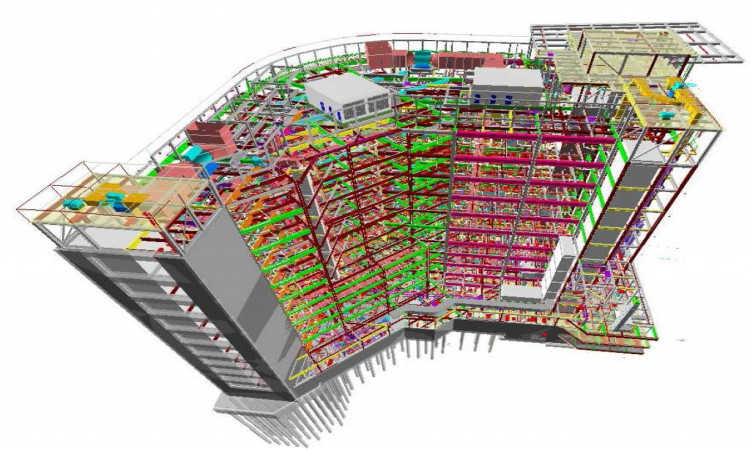

Steel Detailing is the process of detailing and drafting structural components for fabrication. These structural components could be connections, bolts, anchors etc. Using 3D modeling software like AutoCAD, Revit, Tekla etc. provides various advantages like 3D visualization, smooth collaboration, enhanced accuracy, improved productivity, higher profit margins etc. In the current article we will be stating the advantages of Steel Detailing Services.

1. Accurate Calculations:

In the 3D model based approach for Steel Detailing a lot of tasks are done in the software rather than digitally. One of its biggest advantages is precision. For instance, workers in Structural Steel Industry require prior knowledge of mathematics, trigonometry, geometry etc. Using 3D modeling software allows to calculate all this automatically which reduces the scope of human errors as well as augments the speed.

2. Shop Drawings:

Shop Drawings provide all the necessary details for prefabrication of structural components. With BIM’s 3D visualization and clash detection capabilities it is possible to ensure that the 3D model is accurate and there are no clashes which will occur onsite during construction. Shop Drawings that are extracted from the error free 3D model provide the accurate dimensions, sizes etc. required for prefabrication. They ensure that the structural components can be assembled and installed onsite without any significant problems.

3. Cost Benefits:

Cost in any construction project is of paramount importance. Using BIM allows to increase the efficiency and accuracy throughout the project thereby reducing the number of errors drastically. Whenever there is any clash it leads to rework and a waste of resources. All this ultimately leads to a loss of money. For instance, it could be determined on-site that there is a clash between an architectural wall and a structural beam. This would mean design changes and possibly the beam would have to be fabricated again as per the new dimension. Using BIM in the preconstruction stage would have detected this clash between Architectural BIM and Structural BIM Services. Along with it by using 5D BIM it is possible to gain cost estimations, calculate design alternatives and their impact on cost etc.

4. It saves time:

Due to reduction of errors and onsite clashes we can also associate time saving benefits with BIM. Its enhanced collaboration capabilities allow multiple stakeholders involved in the project to work together in the same BIM model significantly decreasing the time taken in the preconstruction stage without affecting the quality. 4D BIM also links time related data to the BIM model and ensures that that there are no scheduling conflicts. It provides start to finish date details about the delivery, assembly, prefabrication etc. It not just saves time but mitigates risk, detects workflow conflicts and provides better end quality deliverables.

Thus, by using BIM for Steel Detailing the AEC professionals can gain tremendous advantages from improved cost margins to better timelines and quality.

Leave a reply

Your email address will not be published. required fields are marked *

{{comments.length}} Comments

{{ comment.name }}

{{comment.datetime}} Reply{{comment.message}}

{{ comment.name }}

{{comment.datetime}}{{comment.message}}