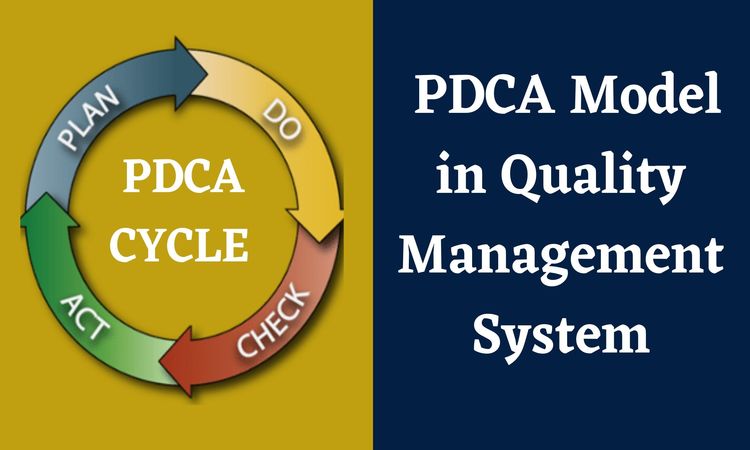

How is the PDCA model used in Quality Management System?

Every company wants to increase its sales and scale its organization, but it's not easy to develop qualitative products that satisfy customer requirements. To produce qualitative products, one company has to go from many processes that will give a satisfying result.

Hence, the companies had to develop the right Quality Management System so that they can manipulate the methods to increase the level of improvisation of the product. And here, the PDCA model plays an important role in building a Quality Management System in the organization.

What is meant by the PDCA model?

The PDCA model is a cycle which is an abbreviation of Plan, Do Check, and Act. Most of the companies use this cycle to improvise and customize the products as per the requirements of the customers. So, we will now take acumen of the working of the PDCA in the organizations.

So, the manufacturing industries and organizations should apply for the ISO Certification Online to develop qualitative products.

How is the PDCA model used in companies?

The PDCA model can be a step by step procedure that works simultaneously with the SDCA cycle or can be used after the implementation of the PDCA cycle. The SDCA cycle is Standardize, Do, Check, and Act, which standardizes the processes and sustains them so that the previous situation does not reflect afterward. The working of the PDCA is explained below:

Planning is an essential first step that should be given more priority as the whole process of production relies on planning. In this stage, the scope of the Quality Management System is defined, and the goals are set to make a product that satisfies customer requirements. The planned procedures are committed across the organization and by the higher authorities in the organization to focus on the customer-centric needs.

After planning on the project, the procedures are executed in the organization that had been scheduled during the Plan stage. The execution or Do stage can be useless if it is executed without a specific goal. Hence the goals that had been planned during the Plan stage stand out and gives a direction to the execution process. This a stage where the processes, products, or services are analyzed and checked. The process and the consequences should match the goals that have been made during the Plan stage, or if it not, then the product may become waste as it is made according to the plan and will satisfy the customers.

In this stage, an action is taken on the issues that had come out during the Check stage if the product does not meet the customer requirements, then the whole process of the PDCA model has carried again till it meets the goals planned in the Plan Stage.

So the improvisation is made frequently in the PDCA model to avoid the defect in the products, and the goals are also updated in the Plan stage based on the situation that arises in the market.

Conclusion:-

The PDCA cycle is mostly used in the organization that follows the ISO standards to develop a Quality Management System. To use the PDCA model effectively, one company should also apply for the ISO Certification in India.

Leave a reply

Your email address will not be published. required fields are marked *

{{comments.length}} Comments

{{ comment.name }}

{{comment.datetime}} Reply{{comment.message}}

{{ comment.name }}

{{comment.datetime}}{{comment.message}}